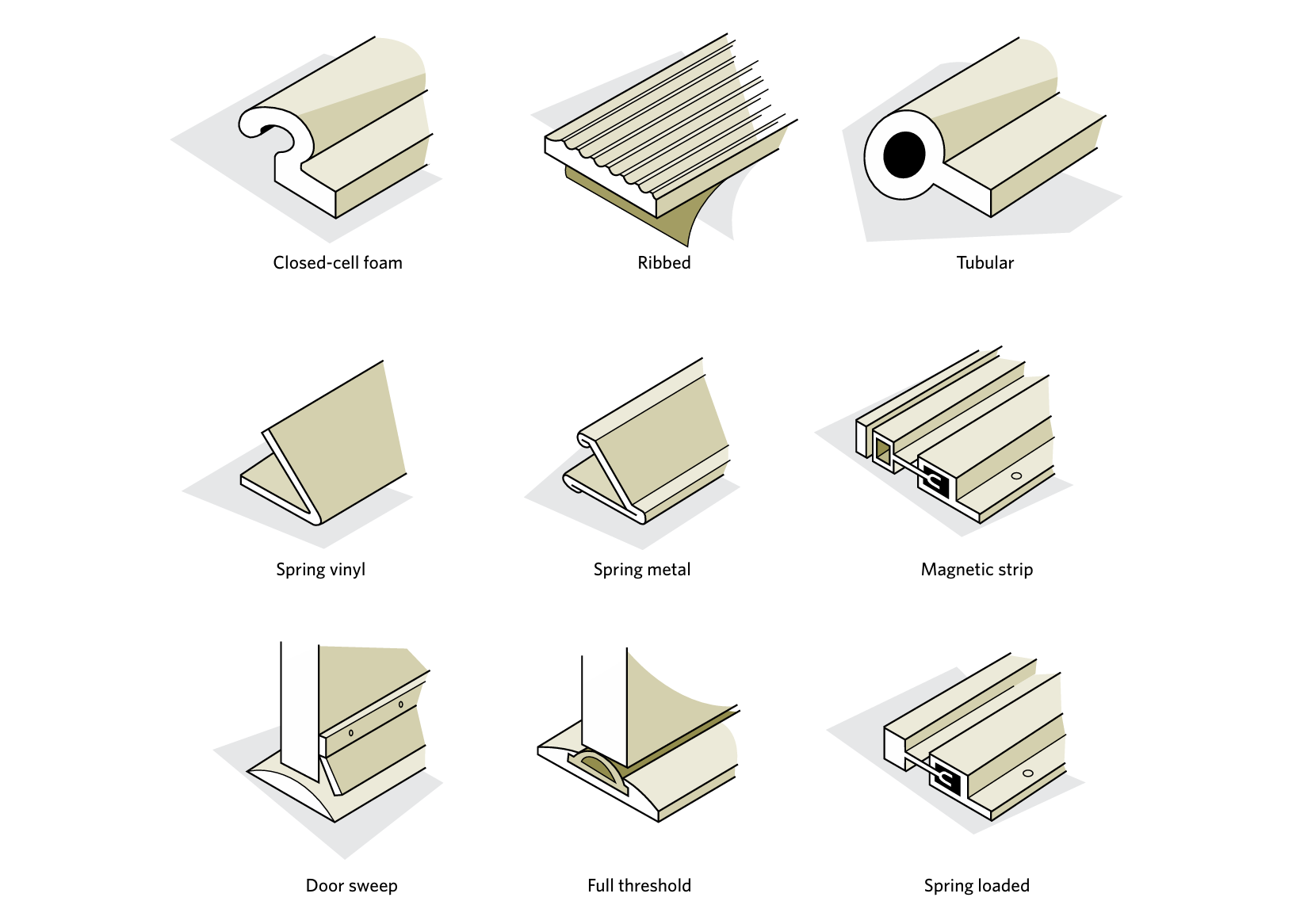

Weatherstripping is used to block air leakage around doors and the operable parts of windows.

Weatherstripping comes in a variety of shapes: flat strip, tube or V (i.e. V-strips), and can be designed to work under compression or by sliding along the joint. To be effective, the product must close the gap and not allow air to pass. Some products get hard – and less effective – in cold weather when you need them the most.

When choosing weatherstripping, consider the size of the gap to be sealed and the durability, ease of installation and finished appearance of the product.

Look for products that are flexible and that spring back to their original shape quickly and easily. Avoid products that make it difficult to operate the window or door. When replacing weatherstripping, bring a sample of the old material to the store with you to ensure that you purchase the correct product.

A wide range of products is available in most building supply stores, including complete sealing

kits. For the best quality weatherstripping, contact window and door manufacturers or installers.

Compression strips

| Category | Application | Installation | Comments |

| Closed-cell foam (with or without vinyl covering) | use where there is a pressure stress: along the bottom of vertical sliding windows, around attic hatches or on hinged windows and doors | adhesive-backed easy to install available in rolls | available as a high-performance compressible polyurethane strip with its own carrier • good for irregular surfaces • vinyl may crack over time |

| Ribbed closed-cell rubber | as above | adhesive-backed • available in rolls • very durable • easy to install | good for irregular surfaces • less appropriate for long or varied gaps |

| Tubular stripping material | as above | has its own attachment or an attachment strip • installed with nails, staples or screws | rubber more durable than plastic • noticeable when installed • check for suitability of use in cold weather |