In the usual order of installation, the floor frame consists of girders or beams, posts or columns, sill plates or mud sill, joists, bridging, and subflooring.

Beams are horizontal load-bearing members that support the inner ends of floor joists. Girders are heavy beams that support other smaller beams. Several types of beams are commonly used.

Beams may be made of solid woodor built up of three or more 2 X (38 X) planks or laminated veneer lumber (LVL) or glulam. Sometimes, wide flange, I-shaped steel beams are used.

Sill plates, also called mudsills, are horizontal members of a floor frame. They bear directly on the foundation wall and provide a bearing for floor joists. It is prudent that the sill be made with a decay-resistant material such as pressure-treated lumber. The sill plate is secured to the foundation wall with anchor bolts or other proprietary anchors (which must be compatible with wood preservatives). Anchor bolts are usually L-shaped and must be embedded at least 4 inches (100 mm) into the concrete. Maximum spacing is 7′ -101h” (2.4 m), and the anchor bolts must be located 6 to 12 inches (152 to 305 mm) in from the end of each piece of sill plate.

Beams may be supported by framed walls, wood posts, or steel columns. Metal plates are used at the top and bottom of the columns to distribute the load over a wider area. The plates have predrilled holes so that they may be fastened to the beam. Notched sections prevent the columns from slipping off the plates. Column size should be determined from the blueprints.

Floor joists are horizontal members of a frame. They rest on and transfer the load to sills and beams. In residential construction, dimension lumber placed on edge has traditionally been used. Wood I-joists, with lengths up to 80 feet (24.4 m), are being specified more often today. Steel framing in the form of joists and walls is sometimes used. In general, when the price of lumber increases significantly or when termites are a problem, steel framing is the solution.

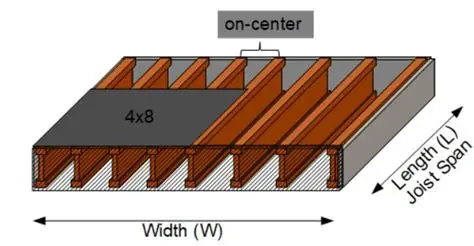

Joists are generally spaced 16 inches (406 mm) OC in conventional framing. They may be spaced 12, 19.2, or 24 inches (305, 488, or 610 mm) OC, depending on the type of construction and the load. The joist spacing is designed so that an 8-foot (2.4 m) section of plywood is fully supported at its ends. Dividing 96 by the number of joist spaces in that section gives the OC. The size of floor joists should be determined from the construction drawings.

Large openings in floors should be framed before joists are installed. This is because room is needed for end-nailing. To frame an opening in a floor, first fasten the trimmer joists in place. Trimmer joists are full-length joists that run along the inside of the opening. Mark the location of the headers on the trimmers. Headers are members of the opening that run at right angles to the floor joists. They must be doubled if they are more than 3′-11 1/4″ (1.2 m) long.

Bridging is installed in rows between floor joists at intervals not exceeding 6′ -11″ (2.1 m). For instance, floor joists with spans of 8 to 14 feet (2.4 to 4.2 m) need one row of bridging near the centre of the span. Its purpose is to distribute a concentrated load on the floor over a wider area. Floor joists that span more than 14 feet (4.2 m) require two rows of bridging. Bridging may be solid wood, wood cross bridging, metal cross-bridging, or 1 X 3 (19 X 64 mm)

Subflooring is used over joists to form a working platform. This is also a base for finish flooring, such as hardwood flooring, or underlayment for carpet or resilient tiles. APA-Rated Sheathing Exposure 1 is generally used for subflooring in a two-layer floor system. APA-Rated Sturd-1-Floor panels are used when a single-layer subfloor and underlayment system is desired. Blocking is required under the joints of these panels unless tongue-and-groove edges are used.