- Brief:

As Canada grapples with housing affordability, modular construction is emerging as a promising solution. Companies like CABN, Stelumar Advanced Manufacturing, and Assembly Corp. are leveraging factory-built, prefabricated components to deliver energy-efficient, cost-effective homes. This article explores how these firms are transforming Canada’s housing landscape. The focus is on the Augusta Township project and broader policy efforts, including Prime Minister Mark Carney’s $26-billion investment to boost home-building productivity.

- Real-World Insights into Modular Construction

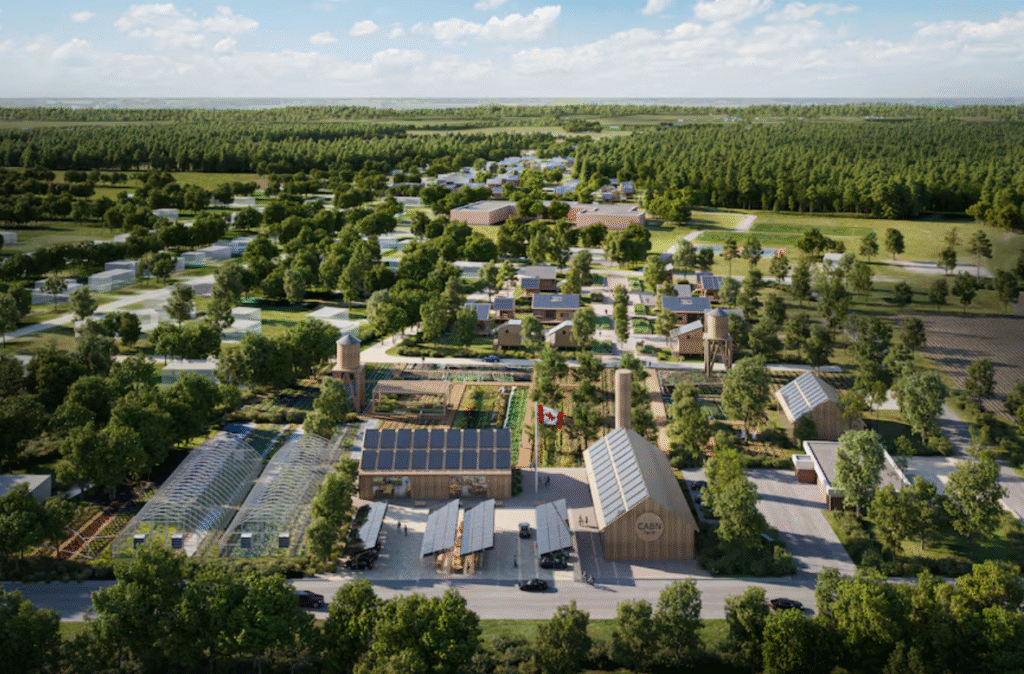

At CABN’s 93,000 square-foot factory in Brockville, Ontario, you will find the production of “flat pack” kits—mass timber-framed wall assemblies with built-in windows, insulation, and cladding. These kits, similar to IKEA furniture, are shipped to sites and assembled in days, reducing construction time and costs. CEO Jackson Wyatt shared that CABN’s process ensures consistent quality, stating, “Our factory-built components are designed to make sustainable housing accessible, regardless of location or budget.”

The Augusta Township project, a 67-unit net-zero community northeast of Brockville, exemplifies this approach. If you tour a two-bedroom showhome designed by B+H Architects and CABN, you will note its renewable energy systems, stormwater recycling, and pedestrian-only pathways. The project’s design, inspired by natural systems like ant colonies, preserves 66% of the 44-acre site as trails and woodlands, enhancing ecological integration.

- Industry Leaders Driving Innovation

Jamie Miller, a senior associate at B+H Architects with over 15 years of experience in sustainable design, explained, “We draw from biomimicry—mimicking natural systems like trees or topography—to create regenerative communities where homes contribute to the energy grid.” His expertise underscores the project’s innovative approach.

Additional insights came from Geoff Cape, CEO of Assembly Corp. and former Evergreen CEO, who is spearheading a consortium to align modular construction with federal policies. Cape’s team is acquiring advanced robotics from Lindbäcks, a Swedish modular construction pioneer, to build a high-tech factory. “These machines will enable precision and scalability,” Cape noted, highlighting how digital design and automation reduce inefficiencies.

Peter Hass, general manager of Stelumar Advanced Manufacturing, also provided technical expertise. With a background in construction logistics, Hass explained how “machine-readable” architectural drawings automate material orders, stating, “This software integration changes the economics of home-building.” Stelumar’s factory, backed by Mattamy Homes founder Peter Gilgan, aims to produce 3,000 homes annually, showcasing the scalability of modular techniques.

- Building Credibility in Modular Construction

The modular construction sector is gaining traction, supported by credible organizations and government initiatives. The Canadian Industrialized Construction Coalition, led by Cape, includes 50 members like Mattamy Homes and Windmill, advocating for tax incentives and infrastructure financing. Their work is informed by global leaders like Lindbäcks, whose century-long expertise in modular building sets a high standard. A 2021 book, The Future of Modular Architecture by New York architect David Wallance, further validates the approach, noting that logistics and software advancements are key to success.

Prime Minister Mark Carney’s $26-billion pledge to enhance home-building productivity, announced in 2025, signals strong federal support. According to a Government of Canada press release, this investment aims to address housing shortages by promoting innovative construction methods. Industry reports from the Canadian Home Builders’ Association also highlight modular construction’s potential to reduce costs by up to 20% compared to traditional methods.

- Challenges and Opportunities

Despite its promise, modular construction faces hurdles. David Wallance, the author of A 2021 bookThe Future of Modular Architecture , notes, “Modular has been the ‘next big thing’ for 50 years, but startups often fail to scale.” For example, Ellis Don’s modular factory near Hamilton struggled due to insufficient demand. However, CABN’s vertically integrated model—owning its factory and controlling production—mitigates this risk. Stelumar plans to supply multiple builders, while Assembly is banking on federal “long-term buy plans” to secure demand, as Cape explained.

Logistics remain critical. Wallance emphasizes efficient shipping as a make-or-break factor, citing past failures like shipping container homes. Modern solutions, like Assembly’s robotic systems and Stelumar’s software-driven supply chains, address these challenges by optimizing production and delivery.

- Sources:

- Interviews with Jackson Wyatt (CABN), Jamie Miller (B+H Architects), Geoff Cape (Assembly Corp.), and Peter Hass (Stelumar).

- Wallance, D. (2021). The Future of Modular Architecture.

- Government of Canada: Housing Investment.

- Canadian Home Builders’ Association: Industry Reports.