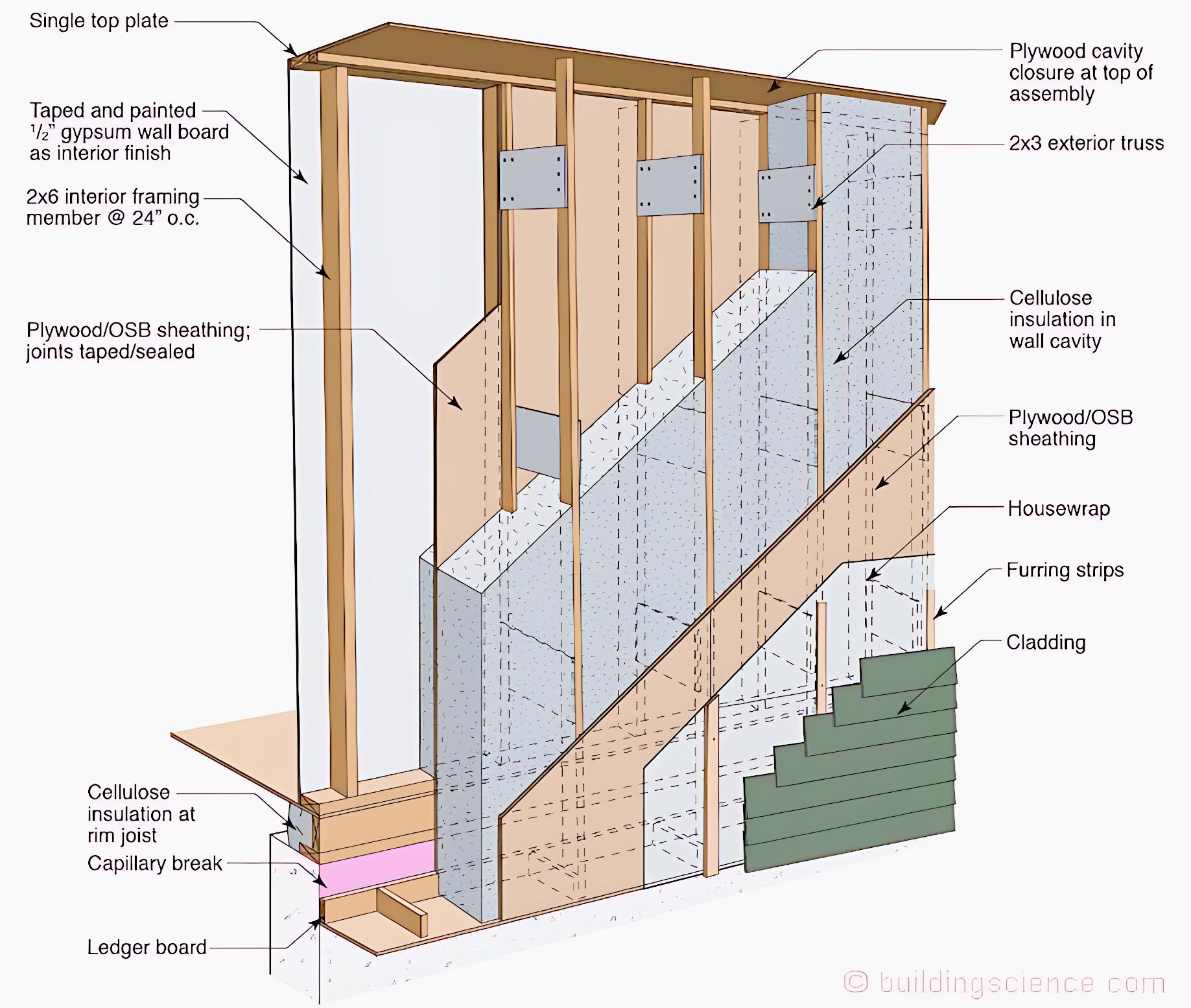

A common strategy in energy-efficient or passive house construction. It shows the various layers and components from the foundation up to the roof transition, emphasizing air sealing, insulation, and moisture management.

Foundation and Base Connection:

* Ledger board: A horizontal board attached to the foundation wall (not fully detailed, but implied below the “capillary break”). This might be used to support floor joists or provide an attachment point for the wall framing.

* Capillary break: A layer (often a durable, impermeable membrane or rigid insulation) placed between the foundation and the wood framing. Its purpose is to prevent moisture from wicking up from the concrete foundation into the wood structure, protecting against rot and mold.

* Cellulose insulation at rim joist: The rim joist is the perimeter framing member of a floor system. This area is often a source of air leakage and heat loss, so it’s insulated, in this case with cellulose, to ensure continuity of the thermal envelope.

Double-Stud Wall Assembly:

* Plywood/OSB sheathing; joints taped/sealed: This is the innermost layer of sheathing, applied directly to the interior side of the inner stud wall. Its joints are taped and sealed to form the primary air barrier of the wall assembly. This is crucial for preventing uncontrolled air leakage.

* 1/2″ gypsum wall board as interior finish: This is the standard drywall that forms the interior finished surface of the wall, applied over the plywood/OSB sheathing. It is “taped and painted” for a smooth finish.

* 2×6 interior framing member @ 24″ o.c.: This refers to the inner structural wall. It’s framed with 2×6 inch studs spaced 24 inches on center. This wider stud allows for more insulation depth.

* Single top plate: The horizontal framing member at the top of the inner wall studs.

* 2×3 exterior truss: This indicates the outer structural wall. Instead of full studs, it uses 2×3 lumber, possibly configured as small trusses or non-load-bearing elements, specifically designed to create a deep cavity for insulation without carrying vertical loads directly. This is a characteristic of double-stud wall systems.

* Cellulose insulation in wall cavity: The large cavity created by the double-stud (or double-truss) wall system is filled with loose-fill cellulose insulation. This provides a very high R-value (thermal resistance) to the wall, significantly improving energy performance.

* Plywood/OSB sheathing: This is the exterior structural sheathing applied to the outer 2×3 framing. It provides racking strength and a substrate for the housewrap.

* Housewrap: A synthetic membrane applied over the exterior sheathing. This acts as a weather-resistive barrier (WRB), preventing bulk water from penetrating to the sheathing while allowing water vapor to escape (it’s “vapor permeable”).

* Furring strips: Vertical strips of wood or other material attached over the housewrap. These create a ventilated air gap (rainscreen) between the housewrap and the exterior cladding. This gap allows for drainage of any water that gets past the cladding and promotes drying of the wall assembly.

* Cladding: The outermost exterior finish material, shown here as horizontal siding (e.g., lap siding or cedar shingles). It’s attached to the furring strips.

Roof/Wall Junction (Top Right):

* Plywood cavity closure at top of assembly: This refers to a piece of plywood used to seal the top of the large wall cavity, ensuring the cellulose insulation is contained and maintaining the air barrier continuity at the transition to the roof structure.

Overall Purpose and Advantages:

This illustration showcases a highly insulated and robust wall system designed for superior energy performance and moisture control, typical in “high-performance“

* High Insulation Levels: The deep wall cavity filled with cellulose insulation provides excellent thermal resistance, minimizing heat loss/gain.

* Effective Air Barrier: The interior taped and sealed plywood/OSB sheathing creates a continuous air barrier, preventing drafts and uncontrolled heat transfer.

* Superior Moisture Management: The combination of a capillary break at the base, housewrap as a WRB, and the ventilated rainscreen system ensures that the wall can effectively shed and dry out any moisture, protecting the structure from rot and mold.

* Structural Redundancy: The double-stud system offers strong structural support while allowing for a deep insulation cavity.