There are several methods of framing a building. Some types are used less often today but still exist, so knowledge of them is necessary when remodelling. Other types are relatively new and knowledge about them is not widespread. Some wood frames are built using a combination of types. New designs utilizing engineered lumber are increasing the height and width to which wood frame structures can be built.

PLATFORM FRAME CONSTRUCTION

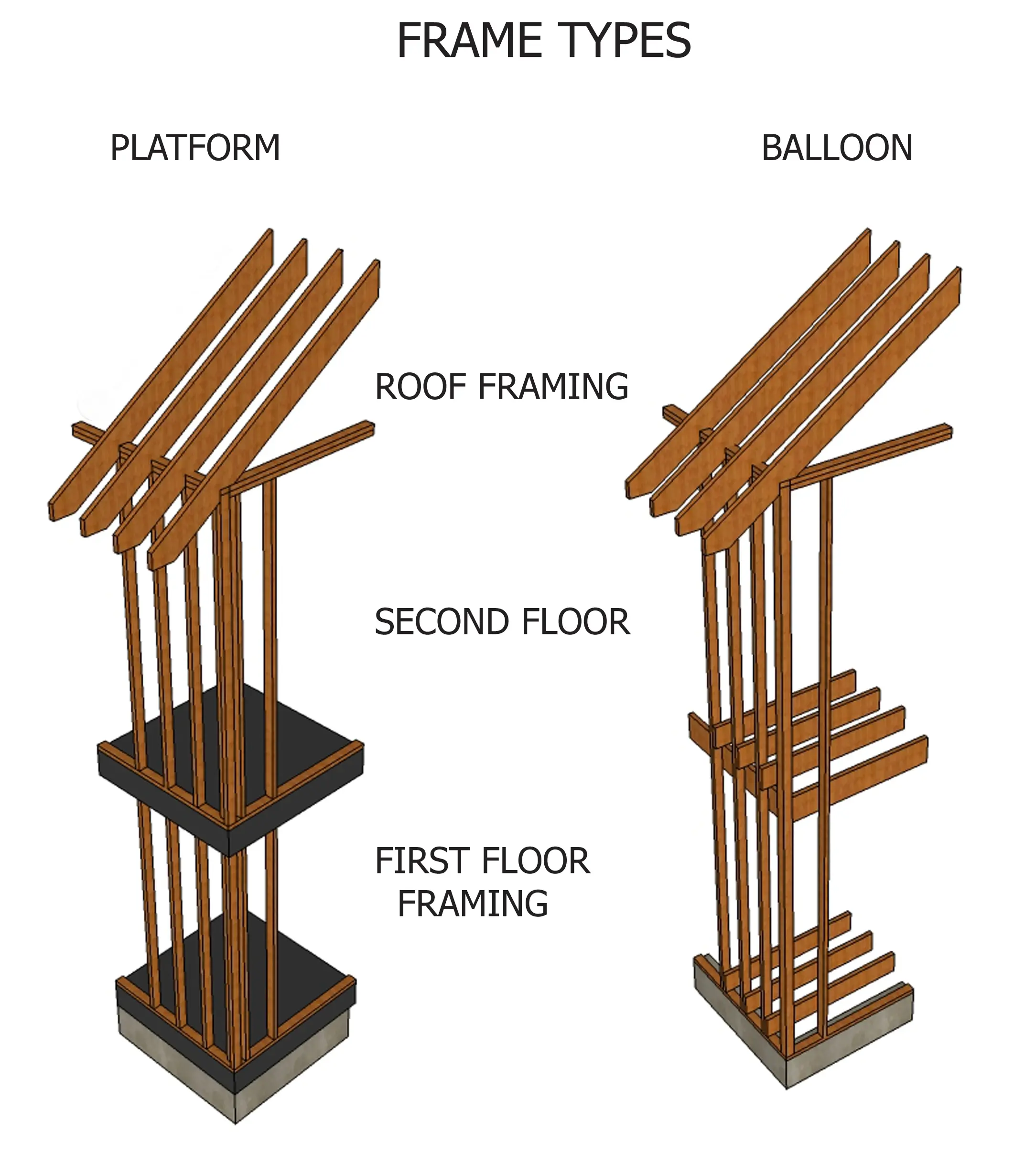

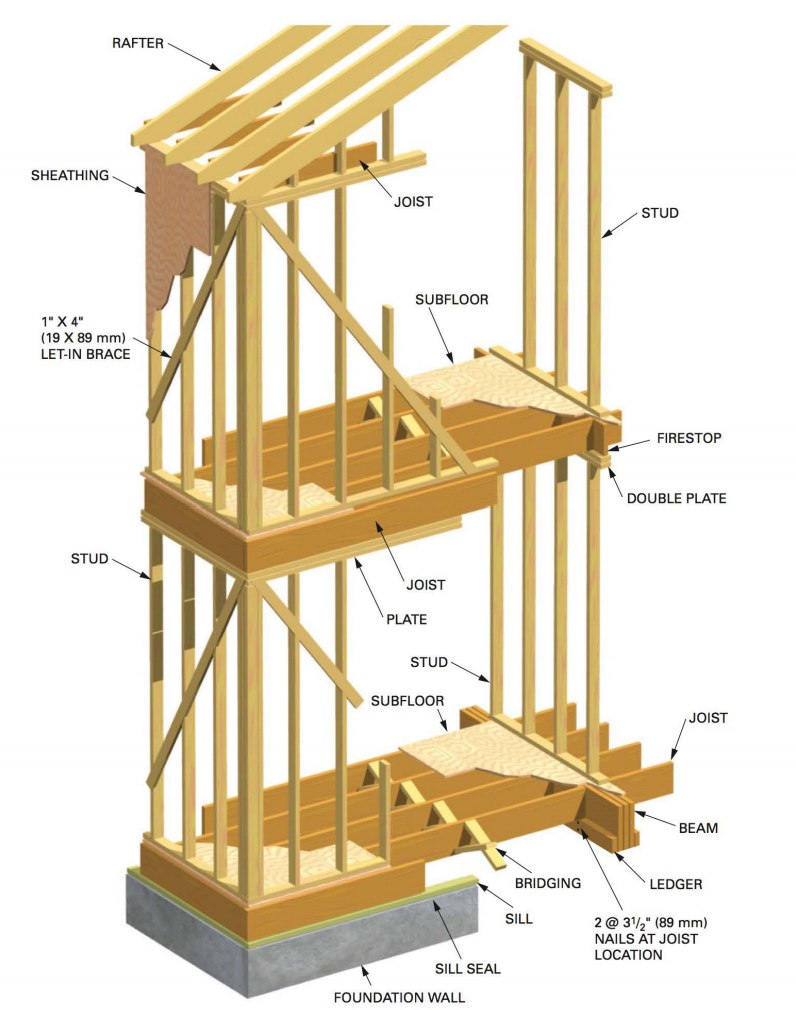

The platform frame, sometimes called the western frame, is most commonly used in residential construction. In this type of construction, the floor is built and the walls are erected on top of it. When more than one storey is built, the second floor platform is erected on top of the walls of the first storey. At each floor level, a flat surface is provided on which to work. A common practice is to assemble wall framing units on the floor and then tilt the units up into place.

Effects of Shrinkage

Lumber shrinks mostly across width and thickness. A disadvantage of the platform frame is the relatively large amount of settling caused by the shrinkage of the large number of horizontal load bearing frame members. However, because of the equal amount of horizontal lumber, the shrinkage is more or less equal throughout the building. To reduce shrinkage, only framing lumber with the proper moisture content should be used (MC < or = 19 percent)

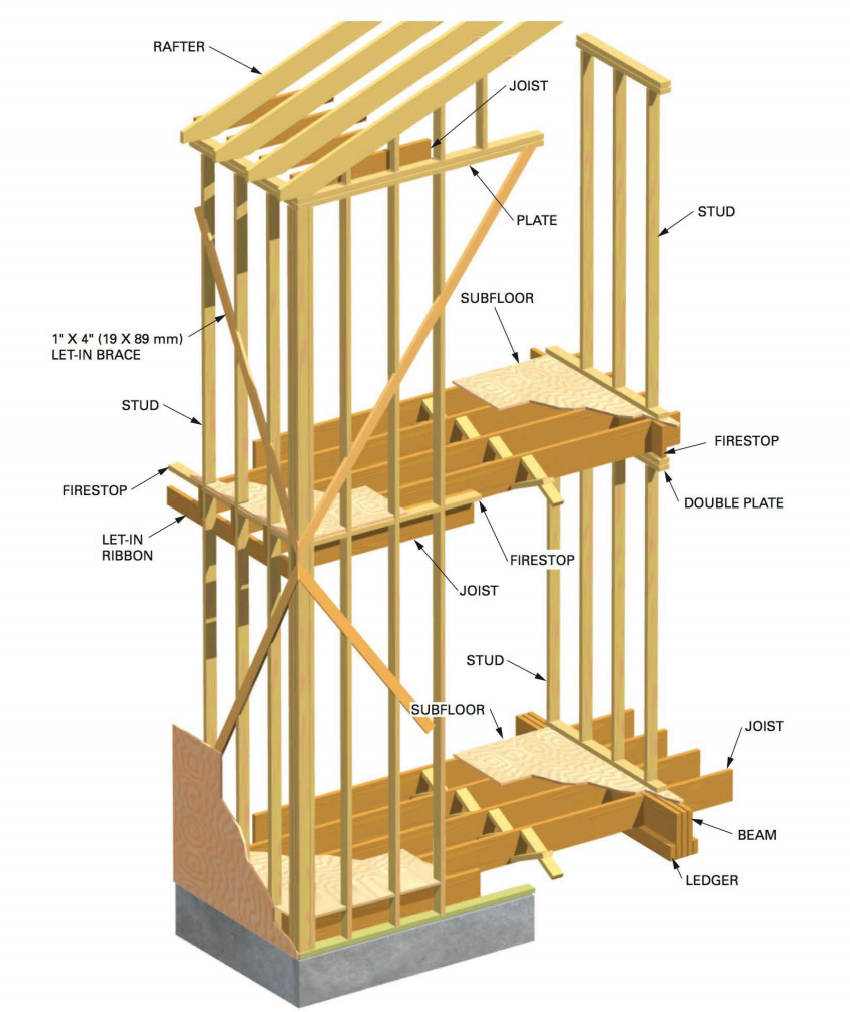

BALLOON FRAME CONSTRUCTION

In balloon frame construction, the wall studs and first-floor joists rest on the sill plate. The second floor joists rest on a 1 X 4 (19 X 89 mm) ribbon that is cut in flush with the inside edges of the studs. This type of construction is used less often today, but a substantial number of structures built with this type of frame are still in use.

Effects of Shrinkage

Shrinkage of lumber along the length of a board is insignificant compared to shrinkage that can occur across the width of the board. Therefore, in the balloon frame, settling caused by shrinkage of lumber is held to a minimum in the exterior walls. This is because the studs are continuous from sill to top plate. To prevent unequal settling of the frame due to shrinkage, the studs of bearing partitions rest directly on the girder or beam.

Most homes today use platform framing—you frame the ground floor, build walls on top, add a second platform (the next floor), and repeat.

Balloon framing, on the other hand, runs long vertical studs all the way from the foundation to the roofline—less common now, but still found in some older homes and used occasionally in open atrium designs.

| Feature | Platform Framing | Balloon Framing |

|---|---|---|

| Easier to build | Yes | No – longer studs, more fire blocking |

| Fire risk | Lower – natural breaks | Higher – fire can spread between floors |

| Insulation | Better (between levels) | Trickier without breaks |

| Best For | Most homes, garages | Tall walls, vaulted ceilings |

If you’re framing alone, platform wins—safer to handle shorter studs and square each floor as you go.

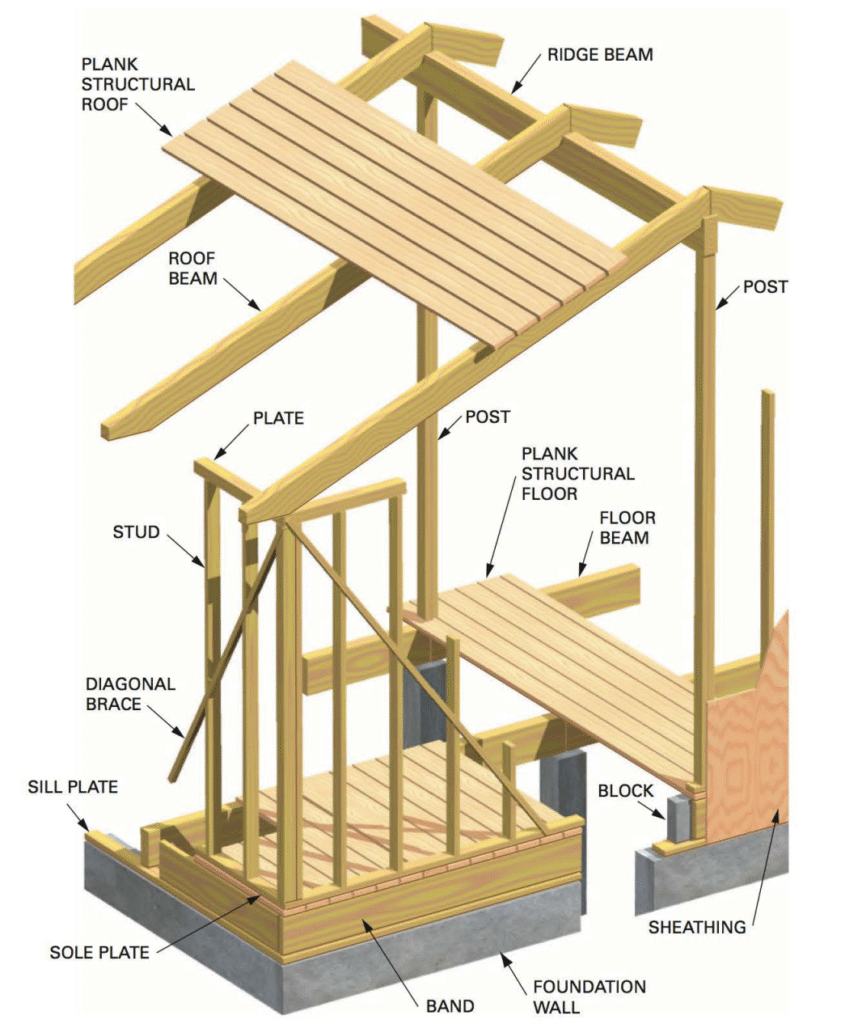

POST-AND-BEAM FRAME CONSTRUCTION

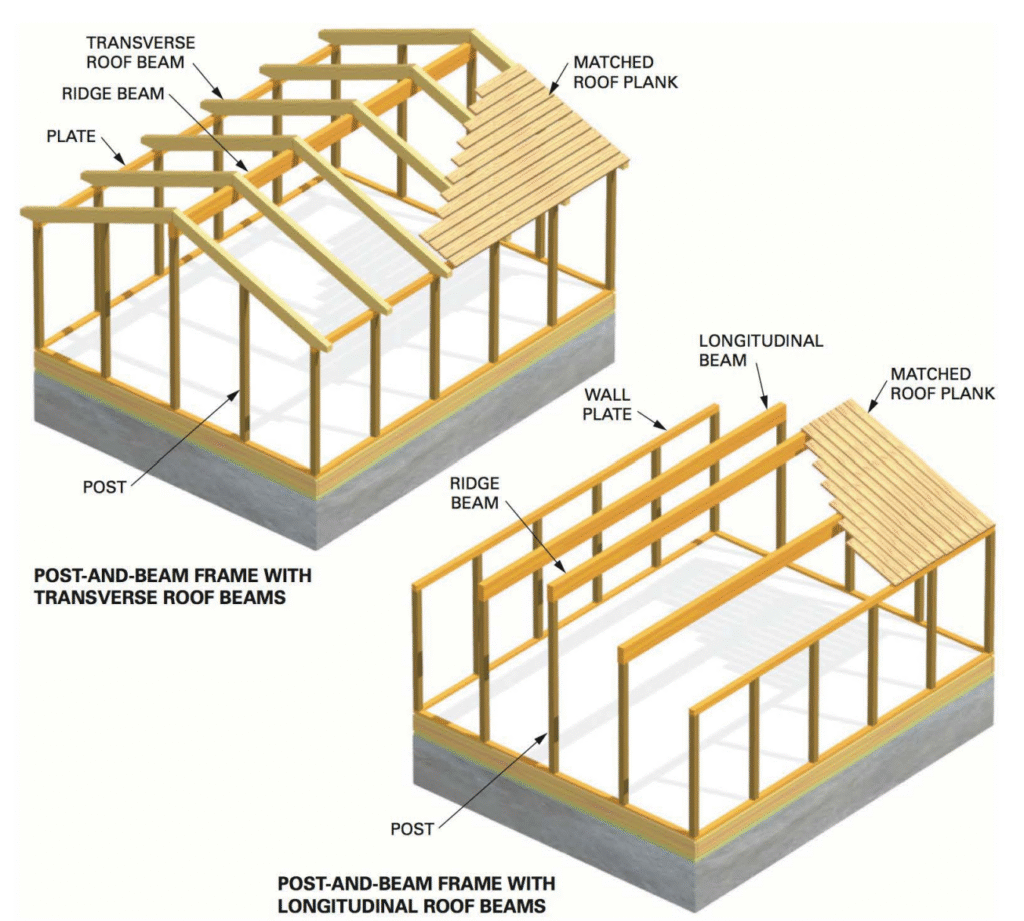

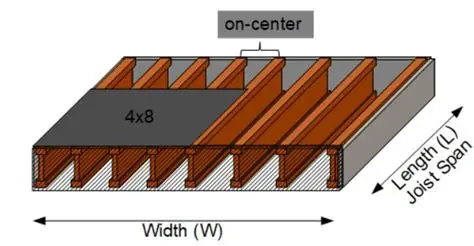

The post-and-beam frame uses fewer but larger pieces. Large timbers, widely spaced, are used for joists, posts, and roof beams. Matched boards (tongue and grooved) are often used for floors and roof sheathing.

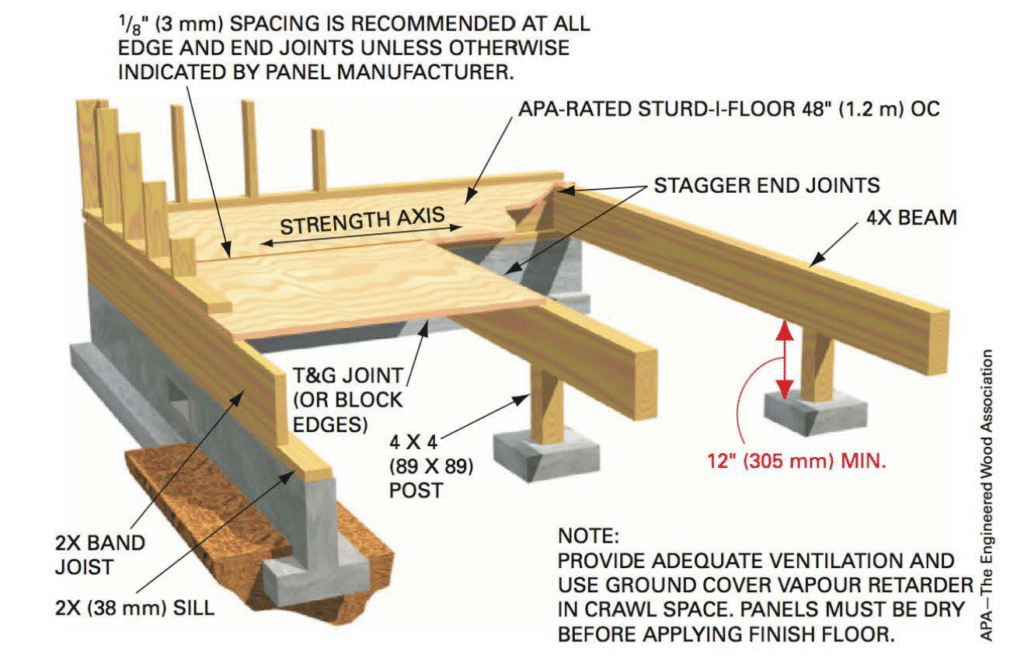

APA-rated Sturd-I-Floor 48 on centre (OC), which is 1 3/32 inches(28 mm) thick, may be used on floor joists that are spaced 4 feet (1.2 m) OC instead of matched boards. In addition to being nailed, the plywood panels are glued to the floor beams with construction adhesive applied with caulking guns. The use of matched planks allows the floor beams to be more widely spaced.

Exterior walls of a post-and-beam frame may be constructed with widely spaced posts. This allows wide expanses of glass to be used from floor to ceiling. Usually some sections between posts in the wall are studded at close intervals, as in platform framing. This provides for door openings, fastening for finish, and wall sheathing. In addition, close spacing of the studs permits the wall to be adequately braced.

The post-and-beam frame roof is widely used. The exposed roof beams and sheathing on the underside are attractive. Usually the bottom surface of the roof planks is left exposed to serve as the finished ceiling. Roof planks come in 2-, 3-, and 4-inch (50,75, and 100 mm) nominal thicknesses. Some are end matched as well as edge matched. Some buildings may have a post-and-beam roof while the walls and floors are conventionally framed.

The post-and-beam roof may be constructed with a longitudinal frame. The beams run paralle to the ridge beam. Or they may have a transverse frame. The beams run at right angles to the ridge beam, similar to roof rafters.

Because of the fewer number of pieces used, a well-planned post-and-beam frame saves material and labour costs. Care must be taken when erecting the frame to protect the surfaces and make well fitting joints on exposed posts and beams. Glulam beams are well-suited for this and are frequently used in post-and-beam construction. A number of metal connectors are used to join members of the frame.